FAQ

Have a question about our products? You can find answers to our most commonly asked questions below. If you still have a question, then please get in touch!

Have a question about our products? You can find answers to our most commonly asked questions below. If you still have a question, then please get in touch!

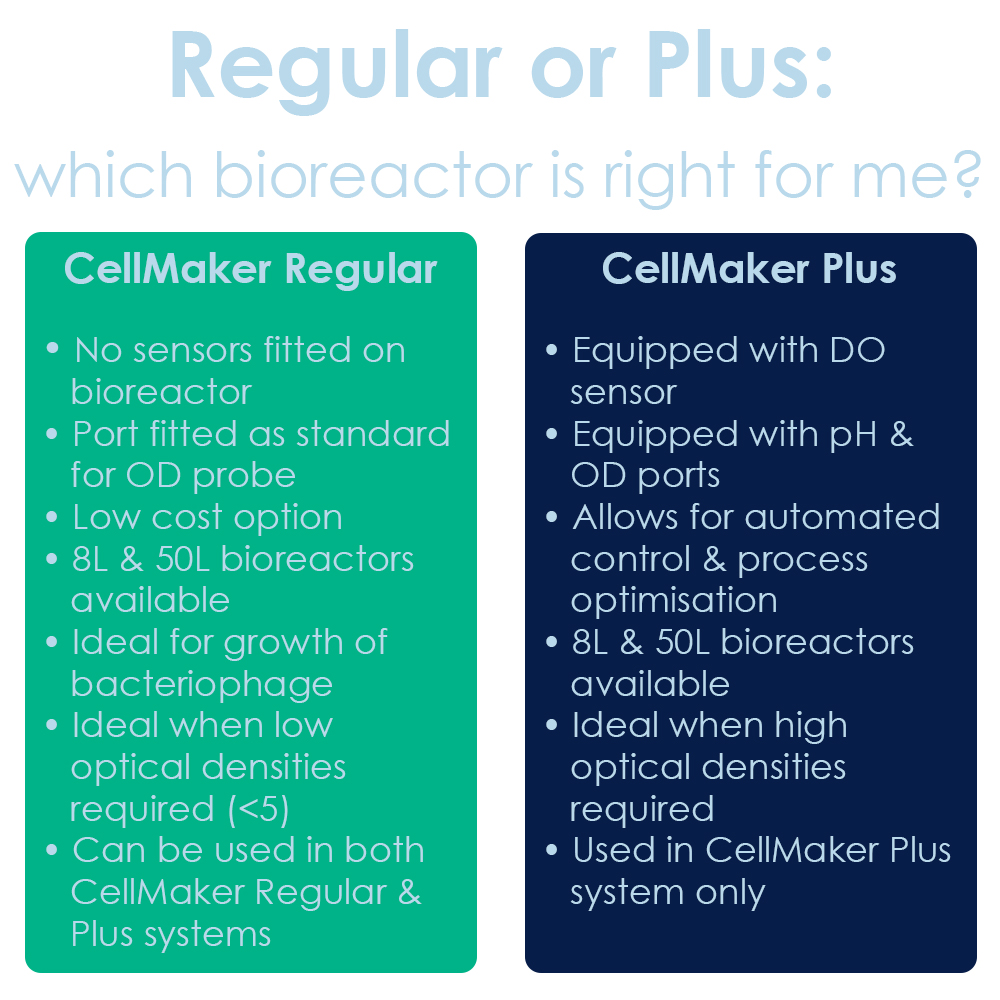

| CellMaker Regular | CellMaker Plus |

|---|---|

| No sensors fitted on bioreactor | Equipped with DO sensor |

| Port fitted as standard for OD probe | Equipped with pH & OD ports |

| Low cost option | Allows for automated control & process optimisation |

| 8L & 50L bioreactors available | 8L & 50L bioreactors available |

| Ideal for growth of bacteriophage | Ideal when high optical densities required |

| Ideal when low optical densities required (<5) | Used in CellMaker Plus system only |

| Can be used in both CellMaker Regular & Plus systems |

The Low Flow Controller is an adaptation of the Plus Controller. It has all the same functionality, but the air flow rate is set exceptionally low, from 0.2 to 2L per minute. This allows for very gentle mixing preferred by more sensitive cells, such as CHO and Hybridoma cells.

Yes! The CellMaker controller is compliant with CFR21 part 11 instruction. Please contact us for more information.

Yes, all our systems are shipped with FAT certification, and we perform Installation and Operation Qualification ‘(IQ/OQ)’ on site upon system purchase.

Our 8L Enclosure has a working volume from 1.5L to 8L, and our 50L Enclosure has a working volume from 10L to 50L.

Using our Dual Regular Controller, you can achieve working volumes up to 100L, as follows:

2 x 8L Enclosures: up to 16L

2 x 50L Enclosures: up to 100L

1 x 8L and 1 x 50L: up to 58L

You can choose from 2 x 8L, 2 x 50L or 1 of each. These run at the same time and you can choose to run the same process or different processes, all managed from the one Controller.

Through experience, we have found out that a short demonstration (for a day or two) doesn’t allow the user to experience the full benefits of the CellMaker. In response, we have created a short-term rental system with very attractive pricing options. Find out more here, or contact us for more information.

The CellMaker can be used for a wide array of cell cultures and fermentations. We work with our clients in their lab to ensure the system is the right fit for their applications and processes.

At the moment, we have successfully achieved growth of bacteriophage, E. coli and other bacteria, mammalian cells and antibodies.

Yes, please contact us for more information.

Sample and analyse offline using a spectrophotometer at 600nm.

If your process requires air only, the CellMaker has a built-in air pump making it a completely stand-alone system.

For processes requiring other gasses, the CellMaker can accept oxygen, carbon dioxide, nitrogen and argon.

The CellMaker can easily achieve temperatures from 16°C to 40°C.

Please contact us to discuss any applications outside of this range.

Yes! As we build the machines in house, we may be able to customise to your requirements depending on feasibility and cost.

We currently offer an 8L and 50L Enclosure for use with our Controller. Using our Dual Regular Controller, you can run two Enclosures at the same time, increasing your production potential to 100L if run with 2 x 50L Enclosures.

We have an in-house Research and Development team who are always looking for ways to improve the system, and we do plan to grow our range in the future.

We offer peristaltic dosing pumps and reusable/ single-use pH sensors, suitable for use with all of our systems.

The CellMaker Bioreactor Bags are made from an inner and outer layer made from low density polyethylene and an intermediate gas-barrier layer of ethylene vinyl alcohol (EVOH). All bags arrive sterile and ready for use.

Then get in touch!

You can email the team on enquiries@cellexus.com, you can phone us on +44 (0) 1382 666 357 or you can submit a contact form.