Interested in finding out more about how CellMaker can improve your workflow? Simply complete the form below and a member of our team will contact you.

At the heart of every CellMaker system is our patented single use airlift bioreactor bags which have been designed to meet the most demanding research and production requirements.

All component bioreactor bag materials are fabricated and assembled in ISO Class VII clean room facilities and according to an ISO 13485:2016 certified, and FDA 21CFR 820 compliant, manufacturing process to ensure you are working with a consistently high-quality product.

Once double bagged and gamma irradiated CellMaker bioreactor bags are stored and dispatched to you according to a robust, ISO 9001:2015 accredited, quality management system providing you with ultimate peace of mind.

Further details and quality certificates are available on request.

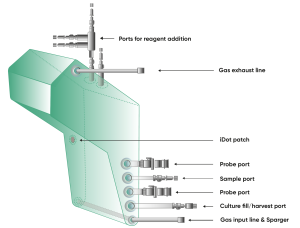

CellMaker Bioreactor Bags are available in 4, 8 and 50 litre capacities with Regular & Plus configurations available in all sizes.

CellMaker bioreactor bags combine the well documented benefits and economy of single use bioprocessing with the scaleability and cell culture improvements afforded by super-gentle airlift technology.

Assembling a CellMaker bioreactor takes just a few minutes so you can be ready to culture very quickly without complicated and involved cleaning, assembly and sterilisation processes to get in the way of your productivity.

As CellMaker employs airlift mixing to ensure correct gassing and efficient mixing of your culture not only are there are no mechanical parts, such as motorised impellers, to worry about but the cells have a much happier time in their own personal spa. As we all know, happy cells are productive cells!

CellMaker bioreactor bags are formed of Renolit 9101 Solmed Infuflex film which is a super-tough, puncture resistant 0.325 mm laminate of biocompatible Low Density Polyethylene (LDPE) and Ethyl Vinyl Alcohol (EVOH) gas barrier to ensure total control of culture conditions, even anaerobic cultures.

The tubing sets used are in all cases PharmaFocus® tubing, a high quality platinum cured silicone tubing which is highly biocompatible making it ideal for use in demanding biomedical/pharmaceutical processes.

All direct product contact parts used in constructing the CellMaker Bioreactor Bags are animal-derived component free or in compliance with the European EMEA/410/01 Rev.3 and CPMP Guideline (CPMP/BWP/1230/98) and have a low extractables/leachables profile.

Regulatory support data, certificates and further information is available upon request.

| Regular | Plus | |

|---|---|---|

| Top ports | 4 | 4 |

| Probe Ports | 1 | 2 |

| Sample ports | 1 | 1 |

| iDot patch (DO Measurement) | No | Yes |

| Media In / Harvest ports | 1 | 1 |